The Allure of Bellow Covers in India

When it comes to protecting and enhancing the performance of machinery, bellow covers India are indispensable. In India, their significance has grown alongside industrial advancement. This post delves into the various aspects of Bellow covers, including their types, materials, applications, and benefits, while highlighting why they are a worthy investment for industries across the nation.

Understanding Bellow Covers

What Are Bellow Covers? https://en.wikipedia.org/wiki/Bellows

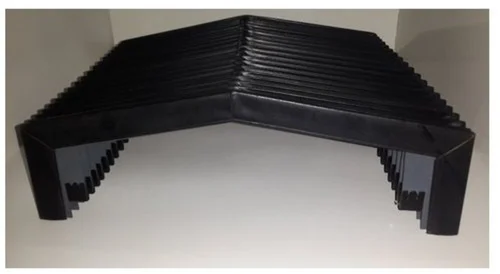

Bellow covers, also known as protective covers or bellows, are flexible enclosures designed to shield moving parts from contaminants such as dust, dirt, and moisture. They play a crucial role in maintaining the longevity and efficiency of machinery by preventing wear and tear on critical components.

Bellow covers are essential; therefore, they provide vital protection for machinery. Not only do they shield components from dust and debris, but they also enhance the overall performance of equipment. Consequently, by investing in high-quality bellow covers, industries can reduce maintenance costs significantly. Additionally, these protective solutions extend the lifespan of machinery, which ultimately leads to greater efficiency. Moreover, choosing the right materials further ensures that the covers withstand various environmental conditions. Thus, in the long run, the benefits of bellow covers far outweigh the initial investment, making them a smart choice for any industrial operation.

Types of Bellow Covers Metallic Bellows

Bellow covers come in various designs to cater to different needs. The most common types include:

- Round Bellows: Often used in applications involving rotary movement, these bellows provide excellent protection while allowing for flexibility.

- Square Bellows: Ideal for linear motion applications, square bellows offer a robust shield against debris and environmental factors.

- Custom Bellows: For specialized machinery, custom bellows can be designed to meet specific dimensions and requirements, ensuring optimal protection.

Material Choices

Common Materials Used

The choice of material for bellow covers significantly impacts their durability and effectiveness. In India, several materials are commonly used:

- Rubber: Known for its flexibility and resistance to wear, rubber is ideal for applications with frequent movement.

- Polyurethane: This material offers excellent abrasion resistance, making it suitable for high-friction environments.

- Fabric: Often used in lighter applications, fabric bellows can be more cost-effective while still providing essential protection.

Factors to Consider

When selecting materials, industries should consider factors such as temperature resistance, chemical exposure, and environmental conditions. Transitioning to a more durable material can lead to significant long-term savings in maintenance and replacement costs.

Applications Across Industries

Diverse Uses of Bellow Covers

Bellow covers find applications in various sectors, including:

- Manufacturing: Protecting CNC machines and robotic arms from contaminants.

- Automotive: Shielding moving parts in engines and transmissions.

- Aerospace: Ensuring the reliability of critical components under extreme conditions.

Case Studies

For instance, in the automotive sector, bellow covers have been instrumental in enhancing the longevity of components subjected to harsh environments. Companies that have invested in high-quality bellow covers report decreased maintenance costs and improved machine efficiency.

Benefits of Investing in Bellow Covers

Enhanced Durability

One of the primary advantages of bellow covers is their ability to extend the lifespan of machinery. By shielding essential parts from wear, they significantly reduce the frequency of repairs and replacements.

Cost-Effectiveness

While there may be an initial investment, the long-term savings associated with reduced downtime and maintenance costs make bellow covers a smart choice. Industries that prioritize preventive measures often find themselves reaping the financial rewards over time.

Improved Performance

Additionally, bellow covers can enhance the overall performance of machinery. By maintaining optimal operating conditions, they help ensure that machines function at their best, leading to increased productivity.

Choosing the Right Supplier

What to Look For

When sourcing bellow covers in India, it is crucial to choose a reliable supplier. Look for companies that offer:

- Customization Options: A supplier that can tailor bellows to specific requirements will be more beneficial.

- Quality Assurance: Ensure that the materials used meet industry standards for durability and performance.

- After-Sales Support: A good supplier will offer support even after the sale, helping with installation and maintenance advice.

Conclusion

In conclusion, bellow covers are an essential component in safeguarding the efficiency and longevity of machinery across various industries in India. Their diverse applications, coupled with the benefits they offer, make them a worthy investment. By choosing the right materials and suppliers, businesses can enhance their operational capabilities and achieve significant cost savings over time. As industries continue to evolve, the role of bellow covers will only become more critical, paving the way for more robust and efficient machinery.