Bellow cover Trumpf laser Machine is available here all types and all shapes .if you are looking for bellow cover for trumpf laser machine in India .it is right place to find out trump make bellow cover covers .we are dealing in bellow covers for all kinds of machines in India. You can visit our website for more details or write us on info@techkome.com.

We are dealing in various types of bellow cover in India you can choose right type of bellow cover for your machine .We will always in front line for support you .

We are Total CNC Solutions situated in Hoshiarpur Punjab .Our customers are spread in all over India .We are supplying bellow covers to our valuable customers from here by transport.

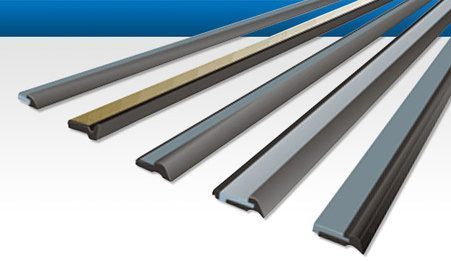

These bellow covers are in c shape ,rectangle shape,round shape ,squareand different types of bellow as per application and requirment.

Different types of fabric used in bellow cover .sometime we are using Para suite fabric and sometime we are using gypsy hood fabric.High temperature fabrics are also used as per requirement.

Our experts are doing job very well to deliver timely service and bonded to deliver good quality products. Dedicated staff and employees are always available to perform their best efforts.

https://techkome.com/bellow-covers-manufacturer-and-supplier-in-india/https://en.wikipedia.org/wiki/Bellow