Discover the Full Range of Bellow Cover Varieties: Complete Protection for Your Machinery

When it comes to safeguarding delicate machinery and equipment, bellow covers play a crucial role. These versatile, protective shields not only extend the life of machinery by preventing dust, dirt, and debris from entering sensitive components but also offer protection against liquids, chemicals, and physical damage. The best part? There’s a bellow cover varieties for every application. From industrial machines to medical devices, these covers come in a range of designs, materials, and configurations, ensuring 100% reliable protection. https://en.wikipedia.org/wiki/Bellows

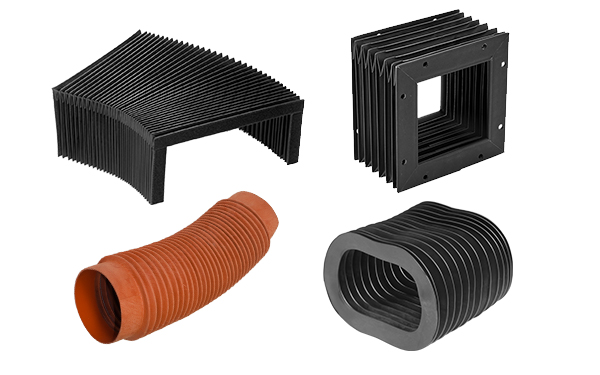

Bellow Cover Varieties

1. Flat Bellow Covers: Simple and Effective

Flat bellow covers are among the most commonly used types due to their simple design and versatility. They are often used for linear movements, offering protection to machinery parts like guide rails and linear actuators.Way Bellow Cover Manufacturer

- Key Advantages: Easy to install, cost-effective, and customizable in size.

- Best For: Machines requiring protection from light dust and small particles in low-impact environments.

2. Round Bellow Covers: Full Coverage for Cylindrical Parts

Round bellow covers, also known as cylindrical bellows, are designed to protect round or cylindrical parts like shafts, pistons, or rods.

- Key Advantages: Perfect for providing full, all-around protection, making them ideal for harsh environments.

- Best For: Hydraulic cylinders, pneumatic actuators, and machine components that are subjected to high wear and tear.

By keeping out dirt and moisture, these covers ensure 100% protection, maximizing the lifespan of moving parts.

Folded Bellow Covers Flexibility and Durability Combined – Bellow Cover Varieties.

Folded bellow covers offer the benefit of high flexibility, allowing them to expand and contract while maintaining their protective function. These covers are highly durable, making them ideal for applications where the machinery needs to move in multiple directions.

- Key Advantages: Provides flexibility for complex movements and offers long-lasting protection even in demanding conditions.

- Best For: Robotic arms, medical equipment, and other devices that require dynamic movement with full shielding.

With 100% adaptability to different machine movements, these covers are excellent for protecting parts that require freedom to move without exposing critical components.

4. Accordion Bellow Covers Maximum Expansion – Bellow Cover Varieties.

- Key Advantages: High capacity for extension and retraction, providing superior protection for longer travel distances.

- Best For: Heavy machinery, elevators, and automotive applications.

Their ability to compress and expand without sacrificing protective capability ensures 100% shielding in environments where both dust and debris are persistent threats.

5. Zippered Bellow Covers: Easy Access for Maintenance

For machinery that requires frequent maintenance, zippered bellow covers offer a unique advantage. These covers feature a zipper design that allows for easy removal, repair, or replacement without disassembling machinery. This makes them highly practical in environments where uptime and efficiency are critical.

- Key Advantages: Easy to remove and re-install, enabling quick access to machine components.

- Best For: Environments where equipment is frequently serviced or maintained, such as laboratories and assembly lines.

This design ensures 100% convenience without compromising on protection, keeping your machinery clean and running smoothly at all times.

6. High-Temperature Bellow Covers: Extreme Heat Resistance

In industries like metalworking or welding, machinery often faces high temperatures that can damage sensitive parts.

- Key Advantages: Withstand extreme temperatures while maintaining full functionality.

- Best For: Applications like furnaces, kilns, and metalworking machinery where components are exposed to intense heat.

With 100% heat-resistant capabilities, these covers ensure machinery remains protected even in high-temperature environments, preventing costly damages.

7. Custom Bellow Covers: Tailored to Your Needs

- Key Advantages: Fully customizable in terms of size, material, and shape.

- Best For: Specialized machinery in industries like pharmaceuticals, semiconductors, and aerospace.

A custom cover guarantees 100% compatibility, delivering unmatched protection tailored to the unique needs of your operation.

The Importance of Choosing the Right Bellow Cover for Maximum Protection

Selecting the appropriate bellow cover is essential for keeping your machinery in top working condition, regardless of the environment or industry in which it operates. By preventing contaminants from infiltrating critical machine parts, bellow covers significantly reduce wear and tear, ultimately extending the lifespan of your equipment. This means less frequent maintenance, fewer repairs, and long-term savings on operational costs.

Moreover, with a diverse selection of bellow cover types—such as flat, round, accordion, and custom options—you can find the perfect solution that fits your specific machinery and application. Whether you’re dealing with high-speed linear movements, harsh industrial environments, or delicate equipment used in medical, aerospace, or manufacturing industries, bellow covers offer 100% protection tailored to your exact requirements. These covers not only provide excellent protection but also offer flexibility, allowing for dynamic movements and ensuring equipment operates smoothly.

Investing in the right bellow cover is about more than just protecting against external damage. It’s about optimizing performance, minimizing downtime, and ensuring the long-term reliability of your equipment. In the long run, choosing the right cover leads to improved productivity, reduced operational costs, and a safer, more efficient working environment for your entire operation.

Conclusion: Finding the Perfect Bellow Cover for 100% Protection

With such a wide variety of bellow covers available, there’s an option for every type of machinery and operational requirement. Whether you need simple dust protection or a solution for high-temperature, chemical-heavy environments, bellow covers offer 100% coverage and peace of mind.

In conclusion, selecting the right bellow cover is essential for ensuring that your machinery operates at peak performance and stays protected from external elements. Whether you’re looking for flexibility, durability, or heat resistance, there’s a bellow cover designed to meet your specific needs. Additionally, using the right cover will extend the lifespan of your equipment, reducing downtime and maintenance costs.

Moreover, with so many varieties available—ranging from flat and round to custom-made options—you can find a solution that guarantees 100% protection. Ultimately, choosing the appropriate bellow cover is not just about shielding your machinery but also about enhancing its efficiency and longevity. So, take the next step today and invest in the perfect bellow cover for complete peace of mind!

So, take the next step today—invest in the perfect bellow cover for your machinery and ensure complete protection, increased performance, and long-term savings.