Accordion Bellow Covers: A Durable Solution for CNC Machine Protection

CNC machines are the heart of modern manufacturing, making it crucial to keep them in top condition. One essential component of maintaining their efficiency and longevity is the use of Accordion Bellow Covers. These protective covers serve a vital function by shielding machine components from dust, debris, and contaminants while ensuring smooth and reliable operation.

Protect CNC Precision with Bellows

Let’s dive deeper into the benefits, applications, and features of Accordion Bellow Covers, explaining why they are a must-have for any CNC machine owner.

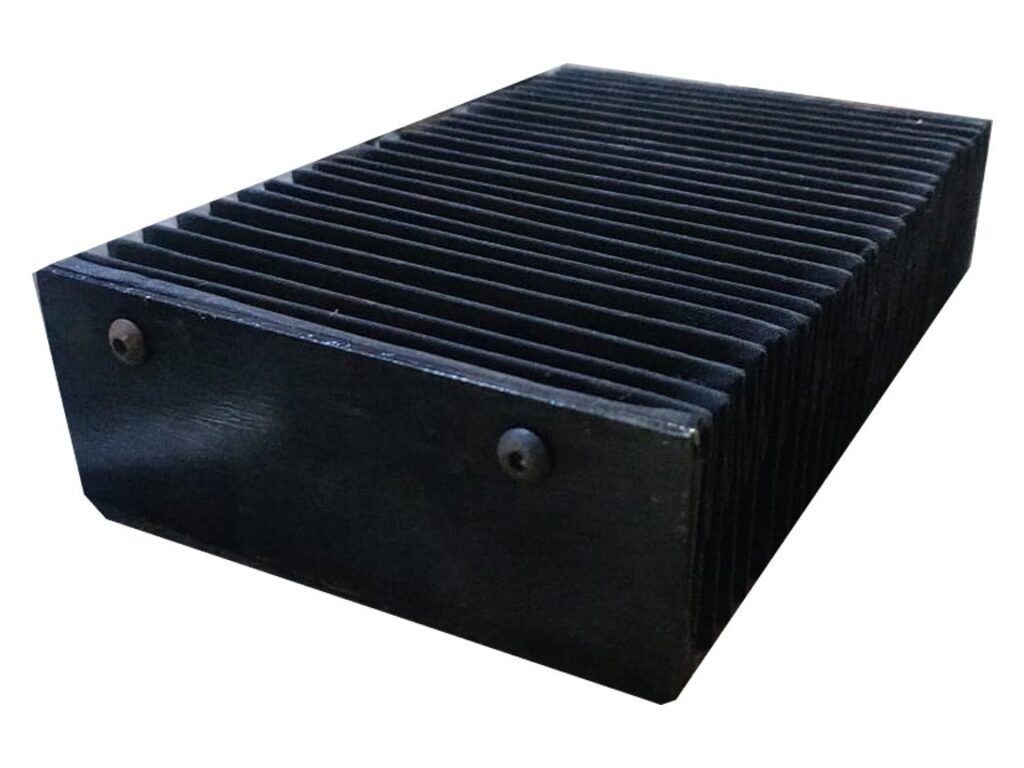

1. What Are Accordion Bellow Covers? https://en.wikipedia.org/wiki/Bellows

They are flexible, multi-layered structures made from high-quality materials, which expand and contract like an accordion. Their primary function is to shield sensitive parts, such as linear guides and ball screws, from contaminants like dirt, dust, and metal shavings.

2. The Benefits of Accordion Bellow Covers

2.1 Enhanced Machine Longevity

First and foremost, these covers significantly increase the lifespan of CNC machines by preventing wear and tear. Contaminants that settle on the internal components can cause damage, leading to costly repairs or downtime. Accordion Bellow Covers act as the first line of defense, ensuring that external factors don’t compromise the machine’s performance.

2.2 Cost-Effective Maintenance

https://en.wikipedia.org/wiki/Bellows

Over time, unchecked debris can clog up machine mechanisms, leading to expensive repair bills. However, with Accordion Bellow Covers in place, routine maintenance becomes easier and more affordable. They help minimize breakdowns and improve the overall operational efficiency of the machine, allowing for smoother production runs with fewer interruptions.

3. Key Features of Accordion Bellow Covers

Accordion Bellow Covers are not only effective but also versatile, adapting to various CNC machine models and working environments.

3.1 Flexible Design

The accordion-like structure allows for flexibility in movement, ensuring that the covers can expand and contract along with the machine’s components. This flexibility is critical for maintaining seamless operations, as it ensures that the cover never interferes with the machine’s movements.

3.2 High-Quality Materials

Durability is another key feature. This makes them suitable for a wide range of industrial applications, where harsh conditions are common.

3.3 Customizable Options

Another important feature is customization. At Total CNC Solutions, we understand that no two machines are alike. That’s why our Accordion Bellow Cover can be tailored to meet specific machine requirements. Whether you need a particular size, shape, or material, we’ve got you covered—literally!

4. Applications Across Industries

Accordion Bellows are not limited to CNC machines. Their versatility allows them to be used in multiple industries, including:

- Manufacturing: To protect machinery involved in metalworking, automotive production, and plastics manufacturing.

- Robotics: To safeguard the sensitive components of robotic arms and automation equipment.

- Medical Devices: Protecting the inner mechanisms of precision medical devices.

Their ability to shield moving parts from environmental hazards makes Accordion Bellow Cover indispensable in any industry where machinery must operate in a contaminant-rich environment.

5. Why Choose Total CNC Solutions for Accordion Bellow Covers?

As a leader in CNC protective equipment, Total CNC Solutions is dedicated to providing high-quality, long-lasting products.

When considering the best way to protect CNC machines, it’s important to explore all available options. First of all, Accordion Bellow Covers provide an excellent solution due to their flexibility and durability. Furthermore, their unique design allows them to expand and contract without restricting movement. In addition, they prevent debris, dust, and contaminants from damaging crucial machine components. Not only do they shield parts from external elements, but they also reduce maintenance costs by minimizing wear and tear. Moreover, their customizable nature ensures they can be adapted to fit various machine models. Similarly, their resistance to oils, chemicals, and extreme temperatures makes them ideal for a wide range of industries. On top of that, Accordion Bellow Covers contribute to overall machine longevity, helping operators avoid costly repairs. Additionally, their easy installation and low-maintenance requirements add convenience for machine operators.

Conclusion: Invest in Protection Today

In summary, Accordion Bellows are an essential investment for any CNC machine operator. They not only extend the life of your equipment but also contribute to better performance and reduced maintenance costs. At Total CNC Solutions, we offer a wide range of customizable options to meet your specific needs. By choosing Accordion Bellow Cover, you’re taking a proactive step toward protecting your valuable machinery and ensuring a seamless production process.

So why wait? Get in touch with us today to learn more about how Accordion Bellow Cover can protect your CNC machines!

Contact Us:

For inquiries and orders, reach out to Total CNC Solutions via email or visit our website to explore our full range of CNC machine protective equipment.