Zippered Bellow Covers: The Ultimate Solution for Easy Maintenance and 100% Protection

When it comes to protecting machinery and ensuring long-term efficiency, bellow covers are essential. However, in many industrial environments, equipment requires regular maintenance, making it critical to have quick and easy access to components. That’s where zippered bellow covers come in. These covers offer a unique combination of full protection and easy accessibility, ensuring that machinery remains both shielded from contaminants and convenient to service. With their user-friendly design, zippered bellow covers provide 100% protection without compromising the ability to maintain and repair vital equipment. https://en.wikipedia.org/wiki/Bellows

What Are Zippered Bellow Covers?

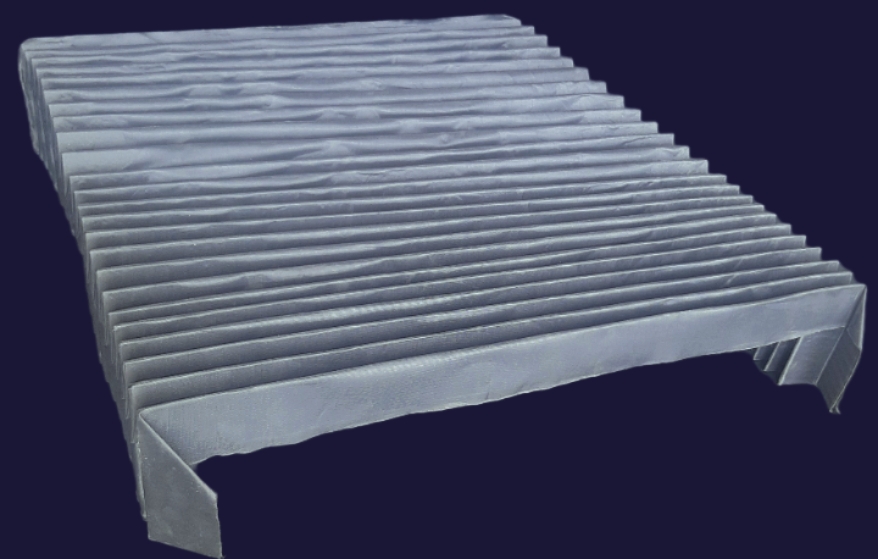

Synthetic Rubber Bellow Covers

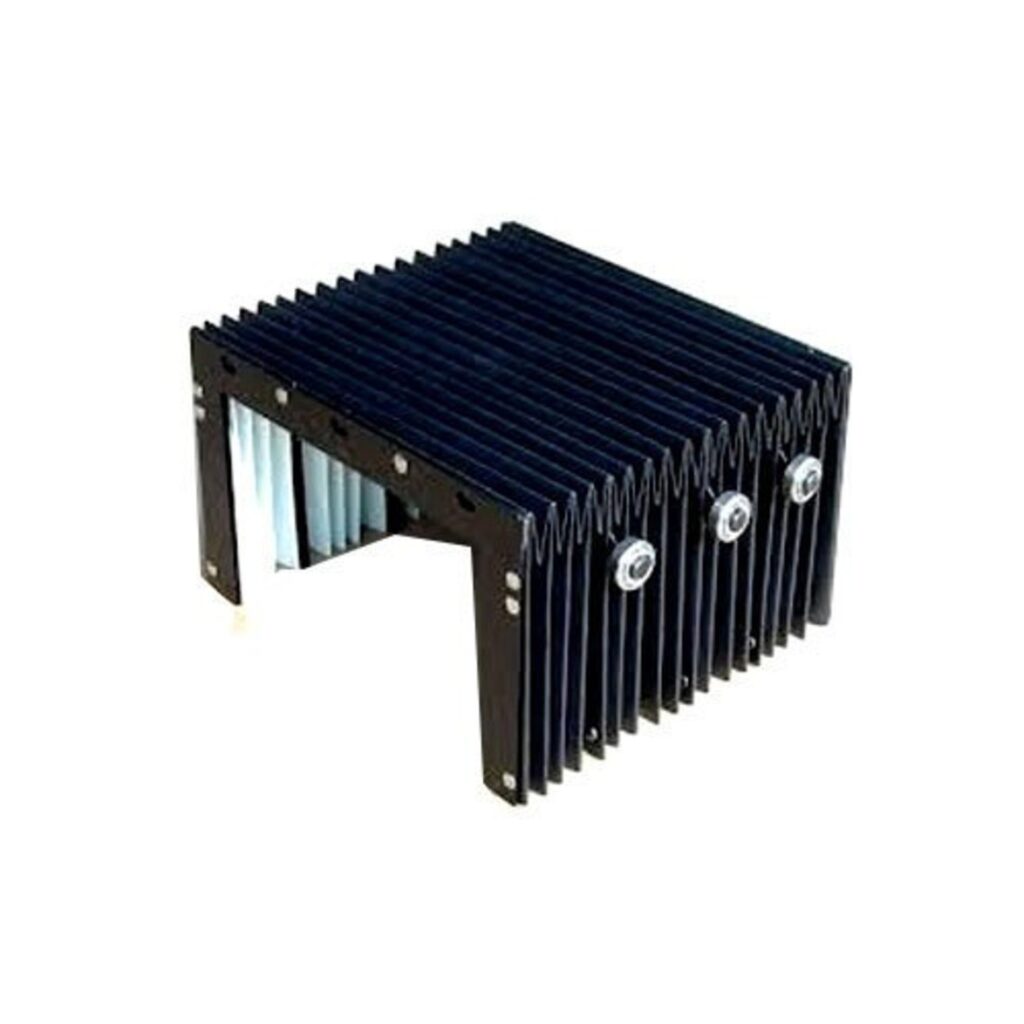

Zippered bellow covers are designed with the same protective features as standard bellow covers, but with the added benefit of a zipper for easy access. The zipper allows users to quickly open or remove the cover without needing to disassemble any part of the machine. This simple yet effective feature ensures that maintenance tasks such as cleaning, lubricating, or part replacement can be carried out efficiently and without downtime.

Moreover, the zippered design allows for quick removal and reinstallation, which can be especially important in environments where time is a critical factor. Therefore, industries that rely on continuous machinery operation, such as manufacturing plants and assembly lines, benefit significantly from this innovation.

Benefits of Zippered Bellow Covers

Zippered bellow covers offer a wide range of advantages, making them an ideal choice for many applications. First and foremost, they deliver 100% protection against dust, dirt, oil, and other contaminants, which can cause wear and tear on critical machine parts. Additionally, their flexible design allows them to easily adapt to the movement of equipment, ensuring complete coverage at all times.

Another key benefit is the easy access they provide. Unlike traditional covers, which can require time-consuming disassembly when maintenance is needed, zippered covers can be opened in seconds. Consequently, they help reduce downtime, increase productivity, and enhance overall operational efficiency.

Furthermore, these covers are available in a wide range of materials, allowing them to meet the specific needs of various industries. As a result, they offer versatility in industries like manufacturing, medical equipment, robotics, and even aerospace.

Easy Maintenance Without Compromising Protection

One of the standout features of zippered bellow covers is their ability to balance protection and accessibility. While traditional covers can be difficult to work with when it comes to maintenance or inspection, zippered versions offer a user-friendly alternative.

https://en.wikipedia.org/wiki/Bellows

In addition, these covers maintain the same high level of protection as their non-zippered counterparts. This means your machinery is still safeguarded from harmful contaminants like dust, chemicals, and debris, but without the hassle of removing an entire cover during repairs. Ultimately, this convenience helps to prevent unnecessary wear, while keeping your equipment running smoothly. CNC Slide Bellow Covers

Moreover, regular inspection and cleaning become much easier with zippered bellow covers. In other words, they make upkeep far simpler and faster.

Customization Options for Any Industry

They come in a variety of sizes, materials, and configurations to suit different machines and environments.

Likewise, if your equipment needs protection from moisture or chemicals, there are water-resistant and chemical-resistant fabrics available.

In fact, industries ranging from heavy-duty manufacturing to precision medical devices can all benefit from tailored bellow covers.

Applications Across Multiple Industries

For example, in manufacturing environments, they protect machine components like linear guides, ball screws, and lead screws from contaminants that could cause damage or malfunctions. In addition, they allow quick access for lubrication or part replacements, which helps minimize downtime and maintain productivity.

Moreover, in the medical equipment sector, zippered bellow covers offer a clean, hygienic solution that ensures easy cleaning and sterilization.

Furthermore, aerospace companies use zippered bellow covers to protect high-performance machinery that requires regular maintenance.

Why You Should Consider Zippered Bellow Covers

In today’s fast-paced industrial world, downtime is costly. The zippered bellow cover helps eliminate unnecessary delays by allowing quick and easy access to machinery for maintenance, repairs, or inspections. At the same time, they deliver 100% protection against contaminants, wear, and environmental damage. This combination of convenience and safety makes the zippered bellow cover an excellent investment for any business seeking to maximize productivity and equipment longevity.

In the end, choosing a zippered bellow cover not only improves the performance and reliability of your machines but also reduces the time and effort required for routine maintenance.

Conclusion: The Perfect Balance of Protection and Convenience

The zippered bellow cover provide the ideal solution for industries that need both robust protection and ease of access.

Ultimately, zippered bellows are the perfect balance of protection and convenience, ensuring that your machinery remains safeguarded without compromising on accessibility.