Scissor Lift Bellow Cover: An Overview

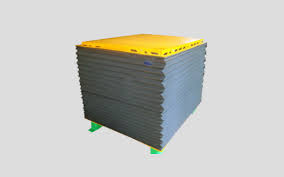

A Scissor lift bellow cover (also known as an accordion cover or bellows) is a protective cover designed to shield the moving components of a scissor lift from contaminants like dust, dirt, oil, and other debris. It typically takes the form of a flexible, expandable accordion shape that stretches and contracts as the scissor lift operates. A Scissor lift bellow cover is a protective shield for the moving parts of a scissor lift.

What is a Scissor Lift Bellow Cover?

A scissor lift bellow cover is a flexible, protective shield placed over the scissor lift’s lift arm joints. This cover is designed to prevent debris, dirt, and moisture from entering the moving parts, which can lead to wear and tear. By serving as a barrier, bellow covers help ensure smooth operation and extend the lifespan of the lift.

The Importance of Scissor Lift Bellow Cover

When it comes to maintaining the functionality and safety of scissor lifts, one often overlooked component is the Bellow cover. This essential part plays a significant role in protecting the lift’s internal mechanisms. Bellow cover India

Custom Solutions

Understanding that each client has unique requirements, we offer tailored solutions to meet specific needs. Whether you need one-off prototypes or large-scale production runs, Total CNC Solutions is equipped to handle it all with flexibility and efficiency.

Materials Used in Scissor Lift Bellow Covers

When it comes to materials, scissor lift bellow covers are typically made from durable options, such as:

- PVC (Polyvinyl Chloride): Known for its strength and chemical resistance, PVC is ideal for environments where chemical exposure is a concern.

- Neoprene: Furthermore, neoprene offers excellent durability and protection against oils and heat.

- Polyurethane: Lastly, polyurethane stands out for its flexibility and abrasion resistance, making it suitable for heavy-duty applications.

Each of these materials is chosen based on the specific requirements of the scissor lift and the conditions it will face.

Benefits of Using Bellow Covers https://en.wikipedia.org/wiki/Bellows

First and foremost, bellow covers provide crucial protection. As previously mentioned, they shield internal components from dust and debris, which can cause mechanical failures. Consequently, using bellow covers can greatly reduce the need for costly repairs and downtime.

Additionally, bellow covers help maintain optimal performance. When the scissor lift’s moving parts remain clean and free from contaminants, they function more efficiently. Therefore, regular inspections and the use of bellow covers can result in improved lift performance and productivity on the job site.

Furthermore, these covers enhance safety. A well-maintained scissor lift minimizes the risk of accidents, making the work environment safer for operators and those nearby. By using bellow covers, operators can have peace of mind knowing that they are taking proactive steps to ensure the lift operates smoothly and safely.

Regular Maintenance and Inspection

In conclusion, investing in scissor lift bellow covers is not just a matter of convenience but a necessity for maintaining the equipment’s efficiency and safety. To maximize the benefits of bellow covers, regular maintenance and inspection are crucial. Check for any signs of wear or damage on the covers during routine inspections. If you notice any issues, replace the bellow cover promptly to ensure continued protection.

Ultimately, protecting critical internal components, enhancing performance, and promoting safety, bellow covers play a vital role in the overall functionality of scissor lifts. Therefore, if you have not already done so, consider incorporating bellow covers into your maintenance routine to keep your scissor lifts in top condition. Prioritize this small yet impactful component and experience the benefits of a more efficient and safer working environment.

Timely Delivery

We understand the importance of deadlines in your projects. Our streamlined processes and efficient production capabilities allow us to deliver your orders on time, helping you keep your projects on schedule without compromising quality.

Applications of Scissor Lift Bellow Covers

- Warehousing and Logistics: In warehouse settings, scissor lift bellow covers protect the equipment from debris and ensure smooth operation.

- Automotive and Aerospace Industries: Similarly, in precision-based industries like automotive and aerospace, these covers maintain the cleanliness and functionality of lifts.

- Construction Sites: On construction sites, where dust and dirt are prevalent, the bellow cover prevents particles from interfering with the lift’s moving parts.

- Manufacturing Plants: Lastly, in manufacturing environments, these covers help ensure long-term efficiency by keeping the machinery running without interruption.

Contact Us

Ready to take your machining projects to the next level? Contact Total CNC Solutions today! For inquiries or to discuss your specific requirements, reach out to us at 7888776715, 9915759967. Our team is here to assist you and provide the solutions you need for your CNC machining projects. Let’s achieve precision together!