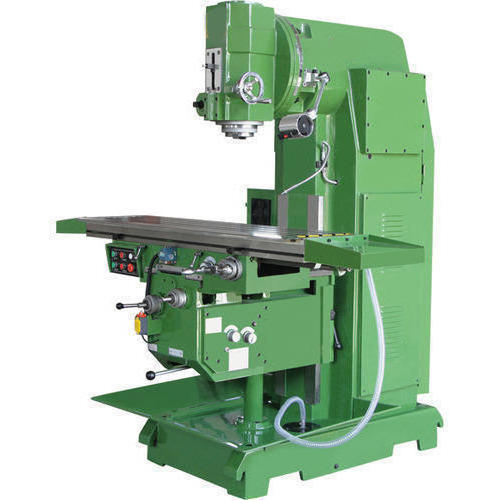

CNC Machine Repair in Jalandhar

We are Total CNC Solutions , Ward no 6 ,Purhiran ,Hoshiarpur. We are providing CNC solutions for all types of CNC machines. We are top in CNC machine repair in Jalandhar.

here is a post on http://https://www.youtube.com/watch?v=SZtLtfS_LCA.hope you would love watching this.

Maintenance of CNC Machines

Maintenance of machines is necessary to increase the machine accuracy and life.There are different types of maintenance in CNC Machines .

Proactive types of maintenance

Preventive Maintenance

Preventive maintenance is the most popular type of proactive maintenance. To start conducting preventive maintenance tasks (PMs), an organization does not need to purchase new technology if it already has a CMMS. This is not the case with predictive maintenance which requires condition monitoring sensors and new software integrations. However, with preventive maintenance, the organization runs the risk of over-scheduling maintenance tasks because tasks are scheduled based on time rather than actual conditions. That said, preventive maintenance achieves 12% to 18% cost savings over reactive maintenance.

Predective maintenance

Predictive maintenance is what savvy maintenance teams aspire to have or are already implementing. The major barrier to is the time it takes to implement rather than the cost of the technology itself. But the time it takes to install, integrate with other maintenance software, and adopt a culture around is not time that all organizations are willing to allocate. For those that do allocate the time, PDM provides an 8% to 12% cost savings over preventive maintenance.

Condition Based Maintenance

Condition-based maintenance is at the core of predictive maintenance but, on its own, does not rely on technology to determine the condition of an asset like PDM does. For instance, a manager may instruct an operator to monitor the condition of an asset and submit a work request when a specific condition is met. This approach may, or may not be, as reliable as predictive maintenance.

Schedule Maintenance

Scheduled maintenance includes work that is scheduled on a calendar for completion. The most common type of scheduled maintenance is calendar-based preventive maintenance tasks. These are scheduled well in advance of completion. For instance, an asset with a monthly PM has twelve instances of scheduled maintenance in a given year. However, just because maintenance is scheduled does not mean it’s planned. Planned maintenance implies that a maintenance planner or other type of maintenance worker has fully planned for parts, materials, skills, and other resources to be available during the scheduled time window.

Planned Maintenance

Planned maintenance is work that’s prepared for in advance of it taking place. A high planned maintenance percentage indicates that a maintenance team will have resources available to complete work for the time/day the work is scheduled for. Having a high planned maintenance percentage also helps boost other maintenance.

Routine maintenance is a form of time-based maintenance and preventive maintenance, though some organizations differentiate between routine maintenance and preventive maintenance. They use the latter for smaller tasks (i.e. cleaning) performed at higher frequencies (hourly, daily) and the former for larger tasks (i.e. inspections) performed at lower frequencies (weekly, monthly, annually). Additionally, routine maintenance is performed by operators, janitors, and other staff member while preventive maintenance is performed by technicians. Non-routine maintenance includes maintenance that is performed re actively or only when needed based on an asset’s conditions.

Reactive types of maintenance

Emergency maintenance

Emergency maintenance occurs when an asset requires immediate attention in order to keep a facility operational or safe. This is the most reactive and intrusive type of maintenance as it pulls technicians away from other jobs and lowers schedule compliance. In extreme circumstances, emergency maintenance can set an organization back days depending on the scope of the repair, available parts, and the asset’s level of importance. To reduce the amount of emergency maintenance that is both unplanned and unscheduled, organizations adopt various forms of proactive maintenance.

Corrective Maintenance

Corrective maintenance is inherently part of emergency maintenance because, when there is an emergency, something needs corrected or fixed. In this way, corrective maintenance is mostly reactive. However, it can also be proactive. If an asset with a condition monitoring sensor detects an issue, a work order is created and a technician is sent to correct it. Similarly, preventive maintenance is considered corrective maintenance if there is an issue to fix. This is rare though as PMs are often conducted when an asset is in good working order.

Total Productive maintenance

Total productive maintenance is the broadest type of maintenance that targets more than the assets that need maintained. It also aims to improve employee satisfaction and overall morale in the workplace, specifically in manufacturing plants. TPM does this by increasing overall equipment effectiveness (OEE) and the amount of planned maintenance. More planned work means more workers have the resources they need to do their job, which means higher levels of satisfaction. TPM also leverages machine operators to participate in maintenance and take ownership of their equipment.

The CNC machine repairing in jalandhar