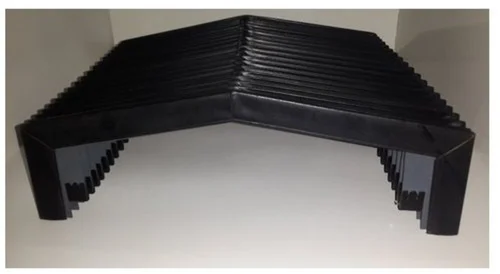

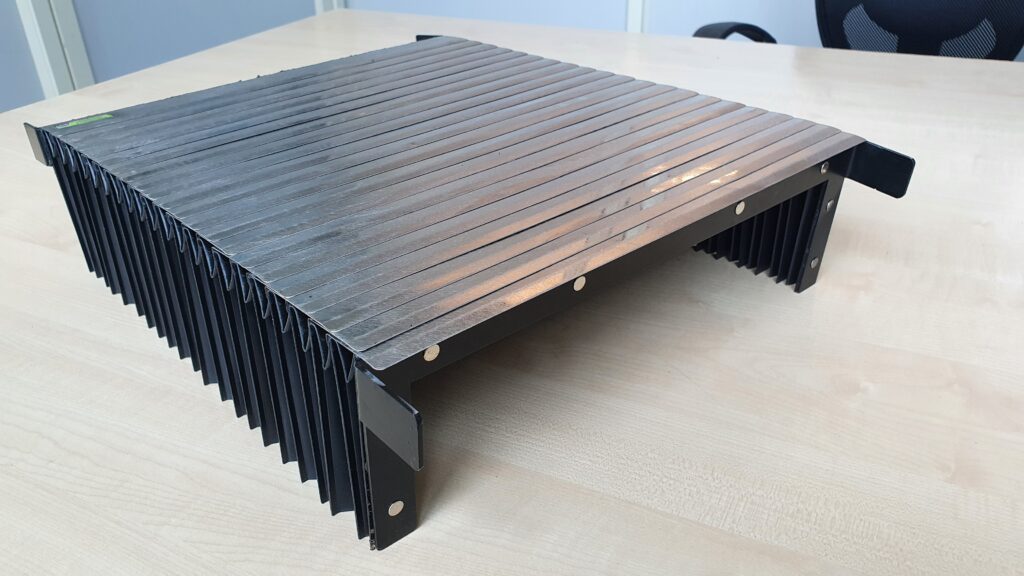

Rubber Coated Fabric Bellow Covers: The Perfect Blend of Flexibility and Durability

When it comes to safeguarding CNC machines and other industrial equipment, rubber coated fabric bellows stand out as a versatile and robust solution. Not only do they offer unmatched protection, but they also ensure optimal machine performance, even in the harshest environments.

Enhances Durability: Rubber coated fabric bellows greatly improve the lifespan of machine components by offering superior protection against contaminants. As machines operate in environments filled with dust, dirt, and other particles, these bellows act as a reliable barrier, preventing harmful substances from reaching sensitive areas. Furthermore, the rubber coating provides excellent resistance to abrasion, ensuring that the bellows themselves can withstand harsh conditions without wearing out. Consequently, investing in rubber coated fabric bellows leads to increased durability and overall equipment reliability.

What Are Rubber–Coated Fabric Bellow Covers?

What Are Rubber Coated Fabric Bellows?

Rubber coated fabric bellows are specialized protective covers designed to safeguard machine components from dust, dirt, liquids, and other harmful contaminants. Made by coating durable fabric materials like nylon or polyester with rubber, these bellows combine flexibility with strength, making them ideal for various industrial applications. Unlike rigid covers, they expand and contract seamlessly, moving with the machine parts they protect. The rubber coating provides added benefits, such as enhanced resistance to chemicals, high temperatures, and abrasion.

In addition to their durability, rubber coated fabric bellows offer several key advantages. First, their flexibility allows them to fit into tight spaces and complex machine setups without hindering movement. Moreover, they adapt to the specific needs of different machines, offering customizable options for maximum compatibility. Furthermore, the rubber coating increases the bellows’ chemical resistance, protecting machines in environments exposed to oils, solvents, and harsh chemicals.

Consequently, industries rely on them to enhance the performance, longevity, and efficiency of their equipment.

Why Fabric Bellow Covers Are Essential for Machine Protection

Next, it’s important to highlight why rubber coated fabric bellows are a must-have for CNC machines and industrial equipment.

Key Features

https://en.wikipedia.org/wiki/Bellows

Now that we’ve discussed their role, let’s dive into the key features of rubber coated fabric bellows:

- Chemical Resistance: The rubber coating offers excellent protection against oils, solvents, and harsh chemicals, ensuring the bellows maintain their integrity in demanding industrial environments.

- High Temperature Tolerance: Whether your machine operates in high-heat conditions or in extreme cold, rubber coated fabric bellows are designed to withstand temperature variations without compromising on performance.

Advantages of Using Fabric Bellow Covers

Moving forward, it’s clear that the advantages of rubber coated fabric bellow go beyond basic protection.

- Enhanced Durability: Rubber coated fabric bellow covers are built to last. By combining the strength of fabric with the durability of rubber, they offer long-lasting protection, even in harsh industrial conditions.

- Versatility: Whether used in CNC machines, medical devices, or automation systems, these bellows are highly adaptable to various applications.

Some important Benefits

- Enhances Durability: Rubber coated fabric bellows significantly improve the longevity of machine components. As a result, they prevent contaminants from damaging sensitive parts, reducing the need for frequent replacements.

- Resists Extreme Conditions: These bellows efficiently withstand harsh environments, including high temperatures, abrasive materials, and chemical exposure. Therefore, they ensure that machinery continues to operate smoothly without compromising on performance.

- Improves Efficiency: By keeping debris, dust, and fluids away from critical machine elements, rubber coated fabric bellows help optimize machine functionality. Consequently, they lead to fewer interruptions and higher productivity levels.

- Minimizes Maintenance Costs: Since rubber coated fabric bellows provide robust protection against wear and tear, they reduce the frequency of maintenance checks and part replacements. In turn, this helps businesses save on operational costs and extend the lifespan of their equipment.

- Increases Flexibility: Unlike rigid covers, rubber coated bellows offer flexibility, enabling them to move with the machine parts. Thus, they accommodate complex movements without restricting or hindering operations.

Applications of Rubber-Coated Fabric Bellow Covers

Now that we’ve covered the benefits, let’s look at where the rubber-coated fabric bellow covers applies.

- CNC Machines: Given the amount of dust, debris, and fluids that CNC machines encounter during operation, rubber coated bellows serve as an essential line of defense, keeping components clean and functioning properly.

- Medical Equipment: In medical and laboratory settings, where precision and cleanliness are paramount, these bellows help protect sensitive instruments from contaminants and ensure smooth operation.

Why Choose Rubber-Coated Fabric Bellow Covers?

Rubber-coated fabric bellow covers provide an excellent combination of durability, flexibility, and protection for your machines. When operating in harsh environments where dust, debris, chemicals, or fluids are present, these covers ensure that critical machine components remain shielded from contaminants. Since the rubber coating enhances the fabric’s resistance to abrasions, high temperatures, and corrosive substances, it allows your equipment to perform at its best without unnecessary wear and tear.

Furthermore, rubber-coated fabric bellow covers offer remarkable flexibility, allowing them to expand and contract with moving parts seamlessly. This adaptability makes them ideal for machines with complex movements, as they do not restrict functionality or hinder performance.

Another reason to select rubber-coated fabric bellow covers is their customizable design options. This ensures a precise fit, offering maximum protection and performance.

Conclusion

In conclusion, rubber-coated fabric bellow covers offer an unbeatable solution for protecting machinery in demanding environments. Their unique combination of durability, flexibility, and resistance to harsh conditions makes them ideal for CNC machines, automation systems, and other industrial applications. By providing superior protection against dust, debris, chemicals, and heat, these covers ensure that your equipment operates smoothly and efficiently, minimizing downtime and reducing maintenance costs. Additionally, their customizable design options guarantee a perfect fit for any machine, enhancing both performance and longevity. Therefore, investing in rubber-coated fabric bellow covers not only protects your valuable equipment but also maximizes productivity and long-term savings.