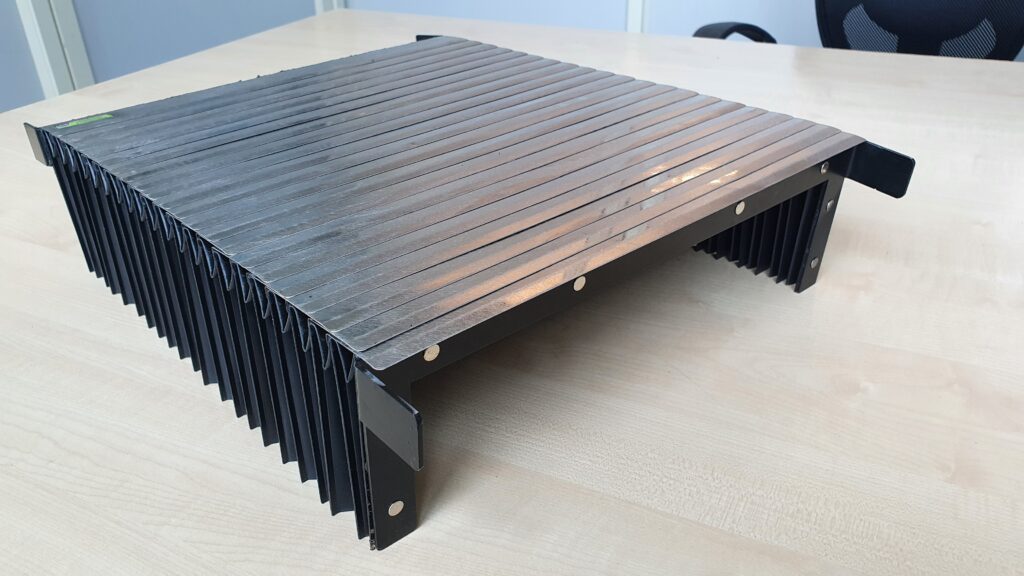

Square Bellow Covers: Essential Protection for CNC Machines

In the CNC machining industry, safeguarding machine components is crucial for ensuring smooth operations and minimizing costly repairs. Square bellow covers are one of the most effective protective solutions available. These covers not only protect machine parts from dust, debris, and coolants but also help extend the life of the equipment. Whether you operate a small workshop or manage large-scale industrial machinery, investing in high-quality square bellow covers is essential for maintaining productivity and reducing downtime.

What Are Square Bellow Covers?

Square bellow covers are flexible, accordion-style protective covers designed to shield critical machine parts like guideways, ball screws, and spindles from external contaminants. Unlike rectangular or round bellow covers, square bellows are specifically shaped to cover square or block-shaped components of CNC machines. These covers expand and contract easily to accommodate the movement of machine parts while providing a protective barrier against harmful elements such as dust, metal chips, and coolant splashes.

Key Features of Square Bellow Covers

Square bellow covers come equipped with several important features that make them a preferred solution for CNC machine protection:

- Perfect Fit for Square Components: Designed specifically for square-shaped machine components, these bellows ensure a snug fit that maximizes protection.

- Durability: Made from tough materials resistant to chemicals, heat, and wear, square bellows provide long-lasting protection, even in harsh working conditions.

- Flexible Movement: The accordion-like design allows the bellows to expand and contract smoothly, following the movement of machine parts without compromising their protective function.

Benefits of Using Square Bellow Covers

By investing in square bellow covers CNC machine operators can enjoy a range of valuable benefits: https://en.wikipedia.org/wiki/Bellows

- Enhanced Protection: Square bellow covers form a physical barrier that prevents contaminants such as dust, metal shavings, and coolant from reaching sensitive machine parts. As a result, machines stay clean and free from damage, which directly translates into better performance and fewer breakdowns.

- Reduced Maintenance Costs: Machines exposed to constant debris buildup are prone to malfunction and wear. Square bellows reduce the need for frequent maintenance by keeping contaminants out, lowering overall maintenance costs and saving time.

- Longer Equipment Lifespan: Protecting vital machine components extends their lifespan. This helps prevent early wear and tear, ensuring machines stay functional and efficient for longer periods, which means fewer replacements and increased ROI.

- Improved Machine Precision: Contaminants like dust and chips can affect the accuracy of CNC machines. Square bellow cover help maintain the precision and smooth operation of machinery by keeping these contaminants away from the moving parts, leading to more accurate production.

Applications of Square Bellow Covers

Telescopic Covers-Bellow Covers

Square bellows are widely used in various industrial applications, especially in environments where CNC machines operate in dusty or debris-prone conditions. Some common applications include:

- Guideway Protection: Square bellows are often used to cover guideways, protecting them from contaminants that could hinder movement or cause damage.

- Ball Screw Shielding: These covers help shield ball screws, ensuring smooth rotational motion while preventing particles from entering and damaging the screw assembly.

How to Choose the Right Square Bellow Cover

Selecting the right square bellow cover for your CNC machine requires careful consideration of several factors. Choosing the correct cover ensures optimal protection and performance:

- Material Selection: Different environments require different materials. For example, machines exposed to chemical coolants may need bellows made from synthetic materials like polyurethane, which offers strong chemical resistance. In contrast, heat-resistant fabrics are more suitable for high-temperature environments.

- Size and Fit: The size of the bellow cover must match the machine’s dimensions precisely. Poorly fitted bellows can lead to gaps in protection or restricted movement. Ensure that you measure the machine components accurately or consult with a supplier for a custom-made solution.

- Operating Conditions: Consider the specific working environment of your CNC machine. For example, if your machine is regularly exposed to fine dust or abrasive debris.

- Flexibility Requirements: The bellow cover must accommodate the movement of the machine without hindering its operation. Opt for covers designed with flexible materials and structures that allow for smooth expansion and contraction.

Why Square Bellow Covers Are the Smart Choice for CNC Machines

Square bellow cover offer a perfect balance between protection, durability, and flexibility. By installing these covers on your CNC machines, you can prevent expensive damage, reduce downtime, and ensure optimal machine performance.

Conclusion: Equip Your CNC Machines with Total CNC Solutions’ Square Bellow Covers

At Total CNC Solutions, we understand the importance of protecting your CNC machines from the elements. Moreover, we customize each cover to fit your specific machine requirements, ensuring optimal coverage and functionality.

extend the life of your CNC machines, and improve overall productivity, trust Total CNC Solutions. Equip your machines with our reliable square bellow cover today and experience the benefits of superior protection!