What are Metallic Bellows?

Metallic bellows are flexible, often accordion-like components made from metals such as stainless steel, titanium, or Inconel. They are designed to accommodate movement and absorb vibrations while maintaining a seal against leaks. This flexibility makes them ideal for various industrial and engineering applications.

Applications Across Industries https://en.wikipedia.org/wiki/Bellows

Here are a few key applications:

- Aerospace: In aircraft and spacecraft, metallic bellows are used in fuel systems and hydraulic lines to handle thermal expansion and contraction.

- Automotive: They are employed in exhaust systems and suspension components to reduce noise and absorb shocks.

- Manufacturing: In machinery and equipment, bellows help in protecting moving parts from contaminants and ensuring smooth operation.

Metallic bellows excel in both durability and flexibility, which makes them ideal for demanding industrial environments. They seamlessly accommodate machinery movement and expansion, thereby ensuring smooth operation. Additionally, their resistance to corrosion guarantees long-term reliability. Furthermore, precision engineering allows for a perfect fit in critical systems, while their versatility supports a wide range of applications across different industries. Consequently, metallic bellows offer a robust and adaptable solution that meets diverse operational needs efficiently.

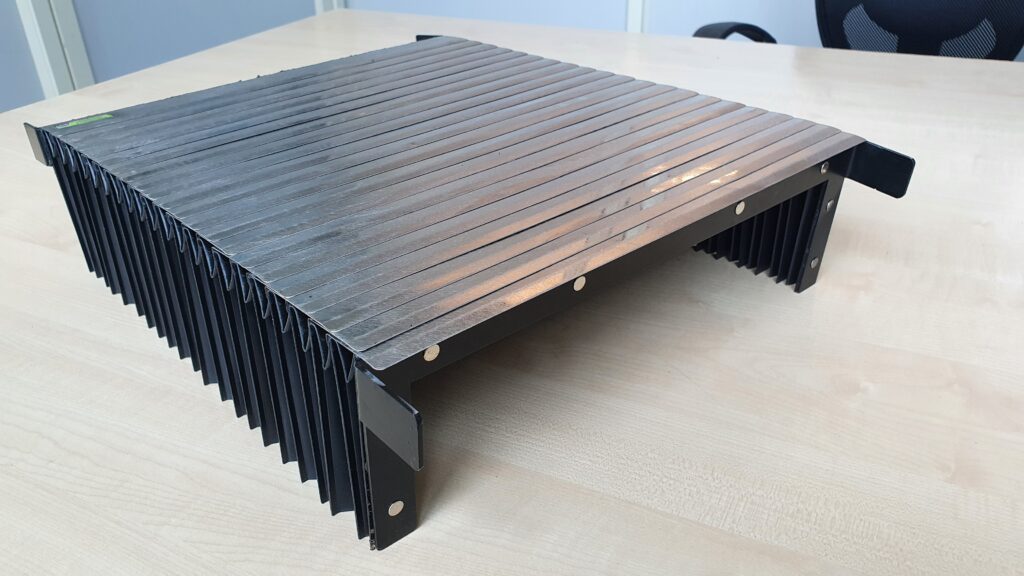

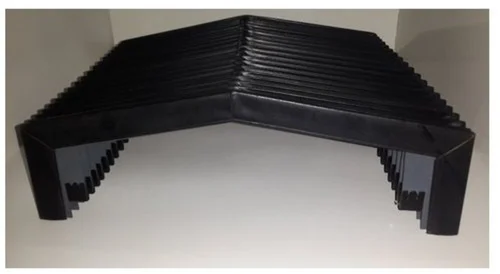

Key Advantages of Metallic Bellows Black Techkome Bellow cover

- Durability: Metallic bellows are highly resistant to extreme temperatures, pressure changes, and corrosive environments. This durability ensures a long service life even under harsh conditions.

- Flexibility: Their design allows them to absorb movements and vibrations, reducing stress on connected components and enhancing overall system performance.

- Sealing: They provide an effective seal against leaks of gases or liquids, which is crucial in many applications to maintain system integrity and efficiency.

- Maintenance: By protecting sensitive components from wear and tear, metallic bellow can reduce the need for frequent maintenance and repairs, ultimately lowering operational costs.

The Deep Benefits of Metallic Bellows

Metallic bellow offer numerous advantages that are vital for ensuring the reliability and efficiency of various systems. Here are some deep benefits of incorporating metallic bellow into engineering and industrial applications:

- Enhanced Durability To begin with, metallic bellows are renowned for their exceptional durability. Due to their construction from high-grade metals like stainless steel or Inconel, they can withstand extreme temperatures and harsh environmental conditions. Consequently, the longevity of metallic bellow reduces the frequency of replacements and repairs, contributing to overall cost savings.

- Superior Flexibility Moreover, the flexibility of metallic bellow is a significant advantage. Their accordion-like structure allows them to accommodate axial movement, lateral displacement, and angular deflection without compromising their integrity. This flexibility is crucial for systems subject to thermal expansion or mechanical vibrations. For instance, in high-speed machinery, the ability of metallic bellow to absorb and compensate for movement prevents excessive strain on other components, thereby enhancing the system’s stability and performance.

- Effective Sealing Capabilities Additionally, the metallic bellow provides excellent sealing properties. They effectively prevent leaks of gases, liquids, and other substances, ensuring that systems operate efficiently and safely. In critical applications, such as in fuel systems and hydraulic lines, the ability to maintain a tight seal is essential for preventing contamination and maintaining pressure.

Corrosion Resistance

An important feature of metallic bellows is their excellent corrosion resistance. This property ensures that they maintain their integrity and performance over extended periods, even in harsh or corrosive conditions.

Precision Engineering

Precision engineering plays a crucial role in the effectiveness of metallic bellows. This precision helps prevent issues such as leaks or misalignment, which can disrupt functionality and lead to costly repairs.

Versatility in Applications

Metallic bellows also excel in versatility. Their ability to adapt to various requirements makes them a valuable component across many different industries.

In addition to flexibility, metallic bellow feature excellent corrosion resistance. This property helps them maintain their integrity and performance over extended periods, even in corrosive or harsh conditions.

Precision engineering is another key aspect of metallic bellows. They are crafted to fit perfectly within critical systems, ensuring reliable operation. This precision prevents issues like leaks or misalignment, which can disrupt functionality and lead to costly repairs.

Overall, metallic bellows combine strength, flexibility, corrosion resistance, and precision to offer robust and effective solutions for diverse industrial needs.

Conclusion

Metallic bellow play a crucial role in maintaining the reliability and efficiency of various systems across multiple industries. Their combination of durability, flexibility, and sealing capabilities makes them a valuable component in modern engineering solutions.