Protect CNC Precision with Bellows: The Key to Long-Term Performance

In the world of CNC (Computer Numerical Control) machines, precision is everything. These machines are essential for producing accurate and high-quality components, but they operate in environments filled with dust, debris, metal shavings, and other contaminants. Over time, these particles can significantly impact machine performance, accuracy, and longevity. That’s where bellow covers come in. They act as a crucial line of defense, ensuring your CNC machine maintains its precision over the long term. Protect CNC Precision with Bellows. PVC Bellows

In this post, we’ll explore how bellow covers protect CNC precision, their benefits, and why they are an indispensable part of any CNC machine maintenance strategy. Bellow Covers At Total CNC

1. What Are Bellow Covers? https://en.wikipedia.org/wiki/Bellows

Bellow covers are a type of protective equipment designed to shield the critical parts of a CNC machine from external contaminants. These covers are typically made from durable, flexible materials such as synthetic rubber, PVC-coated fabrics, or neoprene. They expand and contract like an accordion, allowing them to move along with the machine while protecting its delicate parts from dust, oil, coolant, and other particles.

Not only do bellow covers protect CNC machines from external damage, but they also safeguard the operator by preventing hazardous materials from spreading into the workspace.

Protect CNC Precision with Bellows

Bellow covers are essential for CNC machines because, without them, precision can quickly degrade. First and foremost, they shield sensitive components from dust, debris, and liquids that can otherwise cause damage. In addition, bellow covers help maintain smooth movement, ensuring the machine operates without unnecessary friction or disruptions. As a result, the overall accuracy of the machine is preserved, which is critical in high-precision industries. Moreover, they extend the lifespan of vital components like ball screws and linear guides, which would otherwise wear out prematurely. Ultimately, using bellow covers consistently leads to fewer breakdowns and lower maintenance costs.

Bellow covers play a crucial role in CNC machine protection, primarily because they act as a barrier against contaminants. To begin with, CNC machines operate in environments filled with dust, coolant, and metal shavings, all of which can harm precision components. Furthermore, as the machine moves, these particles can get lodged in the guide rails or screws, leading to misalignment and inaccuracies. Consequently, over time, without proper protection, the machine’s performance deteriorates, affecting both precision and productivity. Additionally, bellow covers prevent external elements from causing friction or jamming, allowing for uninterrupted machine movement. In turn, this results in consistent, high-quality output. On top of that, they contribute to reducing wear and tear on key machine components, which can be expensive to replace. Therefore, by integrating bellow covers into your CNC system, you are not only ensuring smooth operation but also extending the lifespan of the machine itself.

2. The Importance of Precision in CNC Machines

Before diving into the specifics of how bellow covers protect precision, it’s essential to understand why precision matters so much in CNC operations. CNC machines are designed to execute highly accurate and repetitive cuts, drills, or shapes with minimal human intervention. Any deviation from the intended specifications, even by a fraction of a millimeter, can lead to defective products, increased waste, and potential financial losses.

Precision ensures that parts fit perfectly, reduces the risk of rework, and improves overall efficiency. This is why regular protection and maintenance are critical.

3. How Protect CNC Precision with Bellows

Bellow covers provide a reliable shield against harmful particles that can compromise the precision of your CNC machine. Here’s how they help:

- Contaminant Protection: CNC environments are prone to contamination from metal shavings, oils, and coolants. These contaminants can obstruct the smooth movement of machine components and reduce accuracy. Bellow covers prevent this by forming a protective barrier around the machine’s sensitive parts.

- Preventing Component Wear: CNC machines consist of several intricate moving parts that must stay clean to function correctly. Dust and debris can cause these components to wear out more quickly, leading to misalignments or breakdowns. By keeping contaminants away, bellow covers extend the life of precision components such as ball screws, guides, and actuators.

- Ensuring Smooth Movement: Bellow covers move seamlessly with the machine, allowing uninterrupted operation while maintaining a clean environment for moving parts. This smooth movement prevents any jerky motions or disruptions, which could otherwise cause inaccuracies in machining tasks.

4. Types of Bellow Covers and Their Applications

Not all CNC machines require the same type of bellow cover.

- Fabric Bellows: Made from materials like synthetic rubber or coated fabrics, fabric bellow covers are lightweight and flexible. They are ideal for applications requiring moderate protection from dust, water, and oils.

- Plastic Bellows: These bellow covers are more rigid and offer higher durability. They are resistant to chemicals and are typically used in environments where harsh cleaning agents or coolants are in use.

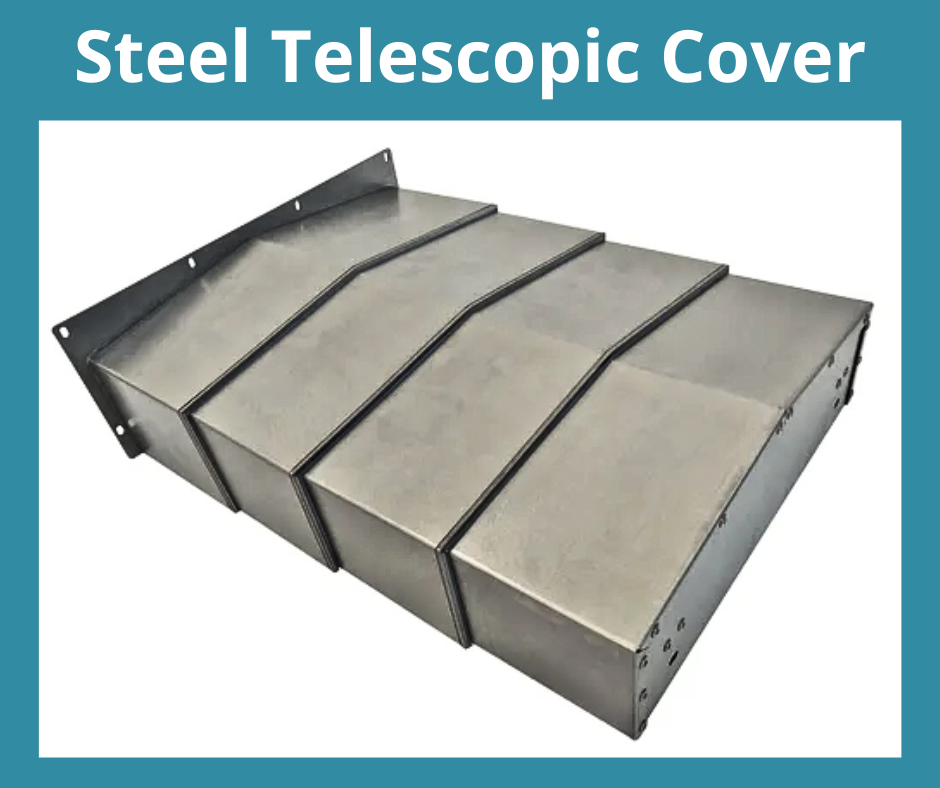

- Steel Bellows: For heavy-duty CNC machines that generate a lot of heat or encounter heavy debris, steel bellow covers are a better option. They provide robust protection against high-impact materials and prevent damage to the machine’s moving parts.

5. The Long-Term Benefits of Using and Protecting CNC Precision with Bellows.

Investing in high-quality bellow covers provides a multitude of long-term benefits for CNC machine operators:

- Extended Machine Life: Protecting sensitive parts from contaminants significantly reduces wear and tear, extending the overall lifespan of your CNC equipment.

- Improved Accuracy: Regular use of bellow covers ensures that critical machine components, such as linear guides and ball screws, remain free of debris and function smoothly. This maintains the machine’s accuracy and prevents costly errors in production.

- Lower Maintenance Costs: By preventing debris buildup and protecting against damage, bellow covers reduce the frequency of machine maintenance and the likelihood of costly repairs. This translates to lower operational costs over time.

6. Incorporating Bellow Covers into Your CNC Maintenance Strategy

Integrating bellow covers into your CNC maintenance plan is straightforward but essential for long-term precision. Here’s how to do it:

- Routine Inspections: Regularly check the condition of your bellow covers for signs of wear, cracks, or tears. If any damage is found, replace the covers immediately to ensure continued protection.

- Cleaning and Care: Depending on the material of your bellow covers, cleaning them periodically with appropriate solutions will help maintain their performance and longevity.

- Proper Installation: Ensure that the bellow covers are correctly installed, fitting snugly around the machine’s components without obstructing movement. Poor installation can lead to inadequate protection and even interfere with machine precision.

7. Why Total CNC Solutions Offers the Best Bellow Covers

At Total CNC Solutions, we understand the critical role that bellow covers play in maintaining CNC precision and overall machine performance. Since 2018, we have been manufacturing and supplying high-quality CNC protective equipment, including fabric, plastic, and steel bellow covers, designed for a wide range of CNC applications.

Conclusion

Precision is the cornerstone of successful CNC machining, and protecting that precision should be a top priority for any operator. Bellow covers offer a simple yet highly effective way to keep contaminants at bay, reduce wear and tear on vital machine components, and extend the life of your CNC equipment. By incorporating high-quality bellow covers into your maintenance routine, you’ll not only improve machine accuracy but also reduce downtime and save on long-term operational costs.

Invest in Total CNC Solutions’ bellow covers and safeguard your CNC machine’s precision for years to come.