Introduction to PVC Bellows

To begin with, PVC bellows are versatile components used across many industries because of their durability, flexibility, and resistance to environmental factors. Moreover, their accordion-like design allows them to expand and contract, therefore making them ideal for protecting moving parts and absorbing vibrations. Furthermore, PVC bellows are a cost-effective solution, as they offer long-term reliability with minimal maintenance. All in all, these features make PVC bellows a popular choice for various applications.

PVC Bellows: A Comprehensive Guide

PVC Bellows are versatile and essential components used in various industrial and commercial applications. Known for their durability, flexibility, and resistance to harsh environments, these bellows serve a critical function in protecting equipment, absorbing vibrations, and compensating for misalignment. In this post, we will explore what PVC bellows are, their key features, applications, and the benefits they offer. Additionally, we will guide you on how to choose the right PVC bellows for your specific needs.

What Are PVC Bellows? https://en.wikipedia.org/wiki/Bellows

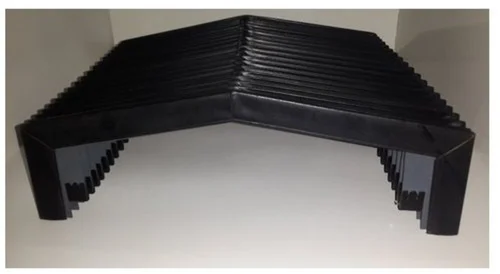

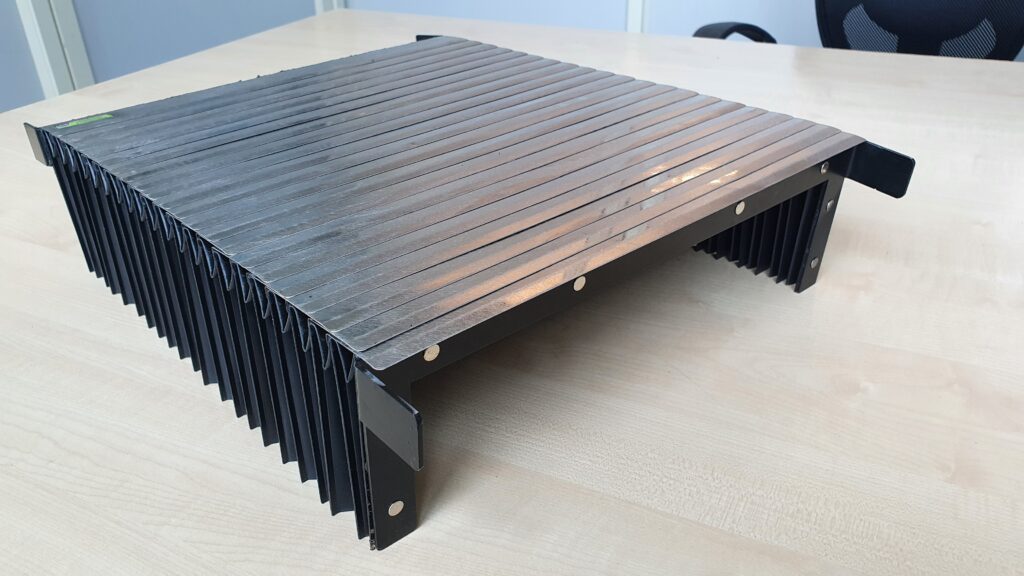

PVC bellow covers are flexible, accordion-like components made from polyvinyl chloride (PVC), a type of plastic renowned for its strength and flexibility. Due to the properties of PVC, the bellow can endure a wide range of environmental factors, including moisture, chemicals, and temperature changes, making them ideal for both indoor and outdoor applications.

How Are PVC Bellows Made? Bellow Covers At Total CNC

PVC bellow covers are typically manufactured using a molding process where the material is heated and shaped into the desired bellow structure. Their foldable design allows them to expand and contract, which helps in absorbing mechanical stress or accommodating movement in pipelines or machinery.

PVC Bellows

In addition, PVC bellow play a crucial role in industrial applications because they offer protection to sensitive components. For example, they shield moving parts from dust, debris, and moisture, which can damage machinery over time. Moreover, they absorb vibrations effectively, preventing wear and tear on equipment. Thus, this leads to increased longevity and better performance. Similarly, PVC bellow accommodate thermal expansion and contraction in piping systems, ensuring flexibility under fluctuating temperatures. As a result, systems maintain efficiency without the risk of leaks or breakage. Furthermore, their chemical resistance makes them ideal for environments with exposure to corrosive substances, ensuring that they continue to perform under harsh conditions. Consequently, industries such as automotive, HVAC, and medical devices rely heavily on PVC bellow for protection and durability. Finally, their lightweight design simplifies installation, reducing labor costs and ensuring a quicker setup.

Key Features of PVC Bellows

When selecting bellow for your application, it’s essential to understand the key features that make PVC bellow stand out. These characteristics include:

- Flexibility: The accordion-like design allows for high flexibility, making them ideal for systems with regular movement or expansion.

- Durability: PVC is known for its strength, which ensures that the bellow can withstand heavy wear and tear.

- Chemical Resistance: PVC bellow covers are resistant to many chemicals, including acids, alkalis, and solvents, making them perfect for harsh industrial environments.

- Weather Resistance: PVC bellow can endure extreme temperatures and are resistant to UV rays, allowing them to perform well in outdoor settings.

Applications of PVC Bellows

PVC bellow covers are used in a wide range of industries due to their protective capabilities and flexibility. Some common applications include:

1. Industrial Machinery

They prevent dust, dirt, and moisture from entering sensitive components, which helps in prolonging the lifespan of the equipment.

2. Automotive Industry

Their flexibility and durability ensure that they can withstand the constant vibrations and movements that occur during vehicle operation.

3. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, PVC bellow Covers serve as expansion joints to accommodate thermal expansion or contraction of ductwork. This helps in reducing stress on the system and ensures a long service life.

4. Pipe and Fluid Systems

They also provide a seal to prevent leaks and protect the system from external contaminants.

Benefits of Using PVC Bellows

1. Cost-Effective Solution

PVC is an affordable material, which makes PVC bellow Covers a cost-effective option compared to alternatives like rubber or metal bellow covers. Despite their lower price point, they still provide excellent durability and protection.

2. Low Maintenance

Thanks to their resistance to corrosion and weather, PVC bellow Covers require minimal maintenance, even in harsh environments. This leads to reduced downtime and lower operating costs.

3. Lightweight

PVC is much lighter than metals, which makes PVC bellow Covers easier to handle and install. This also reduces the load on machinery or structures, which can contribute to longer system life and lower energy consumption.

4. Environmentally Friendly

PVC is a recyclable material, which makes it a more environmentally friendly choice compared to other non-recyclable materials.

How to Choose the Right PVC Bellows

Selecting the right PVC bellow Cover for your application is crucial to ensure maximum efficiency and durability. Here are a few key factors to consider:

1. Size and Dimensions

The size of the bellow must match the equipment or system it is being installed in. Ensure that you measure the diameter and length accurately to get a precise fit.

2. Operating Environment

Consider the conditions in which the bellows will be used. If they are exposed to chemicals, moisture, or high temperatures, make sure the PVC material is rated for those conditions.

3. Flexibility Requirements

Some applications may require more flexibility than others. Choose a PVC bellow with the appropriate level of expansion and contraction based on the movement or vibrations it will need to absorb.

4. Pressure and Vacuum Rating

Depending on the system, the PVC bellow Covers may need to handle pressure or vacuum conditions. Always verify the pressure rating to ensure it will not fail under the operating conditions of your system.

5. Customization Options

Many manufacturers offer customization options for dimensions, material thickness, and mounting styles, so be sure to inquire about these possibilities if required.

Final Thoughts on PVC Bellows

In conclusion, PVC bellow covers are an excellent choice for a variety of industries, as they combine flexibility, durability, and cost-effectiveness. Moreover, their ability to resist harsh environmental conditions, such as chemicals and extreme temperatures, makes them ideal for both indoor and outdoor applications. Additionally, because of their low maintenance and long lifespan, they help reduce operational costs over time. Furthermore, their lightweight design ensures easy installation and minimal strain on equipment. Whether you need to protect machinery, absorb vibrations, or accommodate system movements, PVC bellow offer a reliable and efficient solution. All things considered, with the option for customization, they can easily meet the unique needs of any application.