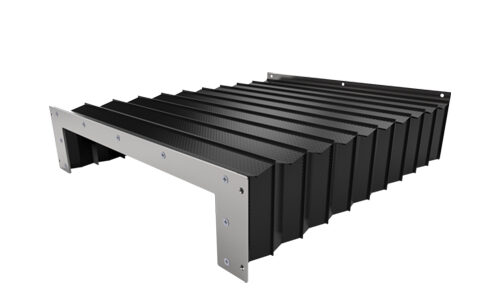

Nylon Bellow Covers: The Ultimate Protection for CNC Machines

CNC machines are the backbone of modern manufacturing, and keeping them in optimal working condition is essential for productivity and efficiency. Among the various components that help protect these machines, Nylon Bellow Covers stand out as one of the most reliable solutions. Designed for durability and flexibility, these covers provide unparalleled protection for the moving parts of CNC machines, safeguarding them from dust, debris, coolant, and other contaminants.

Protect CNC Precision with Bellows

When selecting Nylon Bellow Covers for CNC machines, it’s essential to understand their numerous advantages. First and foremost, their flexibility ensures smooth compatibility with moving parts, making them highly efficient in protection. Moreover, the durable nylon material is designed to withstand wear and tear, ensuring long-lasting use in demanding environments. Additionally, their resistance to oils, chemicals, and high temperatures further increases their reliability. Furthermore, Nylon Bellow Covers help reduce maintenance costs by preventing contaminants from reaching vital machine components. As a result, CNC machines experience fewer breakdowns and longer operational life spans. On top of that, the lightweight design of these covers minimizes strain on the machine, allowing for faster, smoother operations. Similarly, their customizable options make them adaptable to various machine types, ensuring a perfect fit.

1. What Are Nylon Bellows?

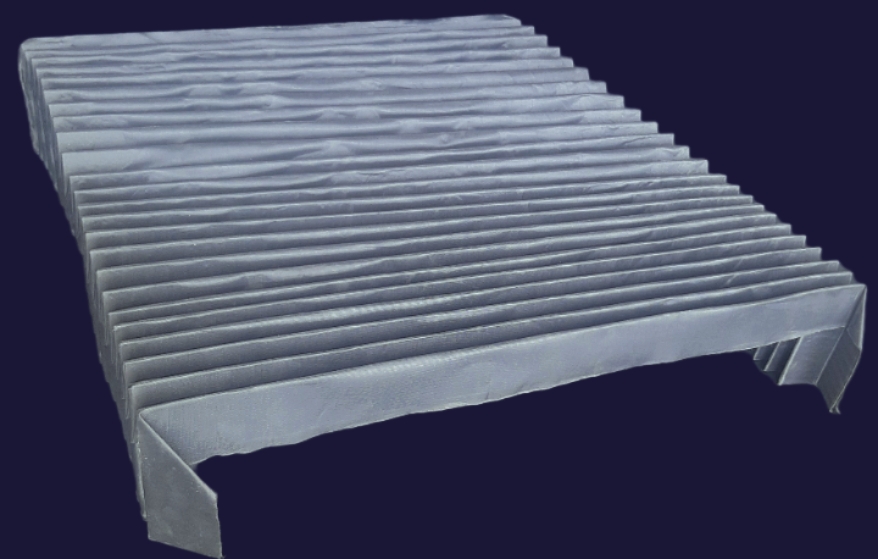

Made from high-quality nylon fabric, these covers are known for their strength, resilience, and flexibility. The accordion-like structure allows the covers to expand and contract along with the machine’s movements, offering seamless protection without hindering operation.

2. Why Choose Nylon for Bellows?

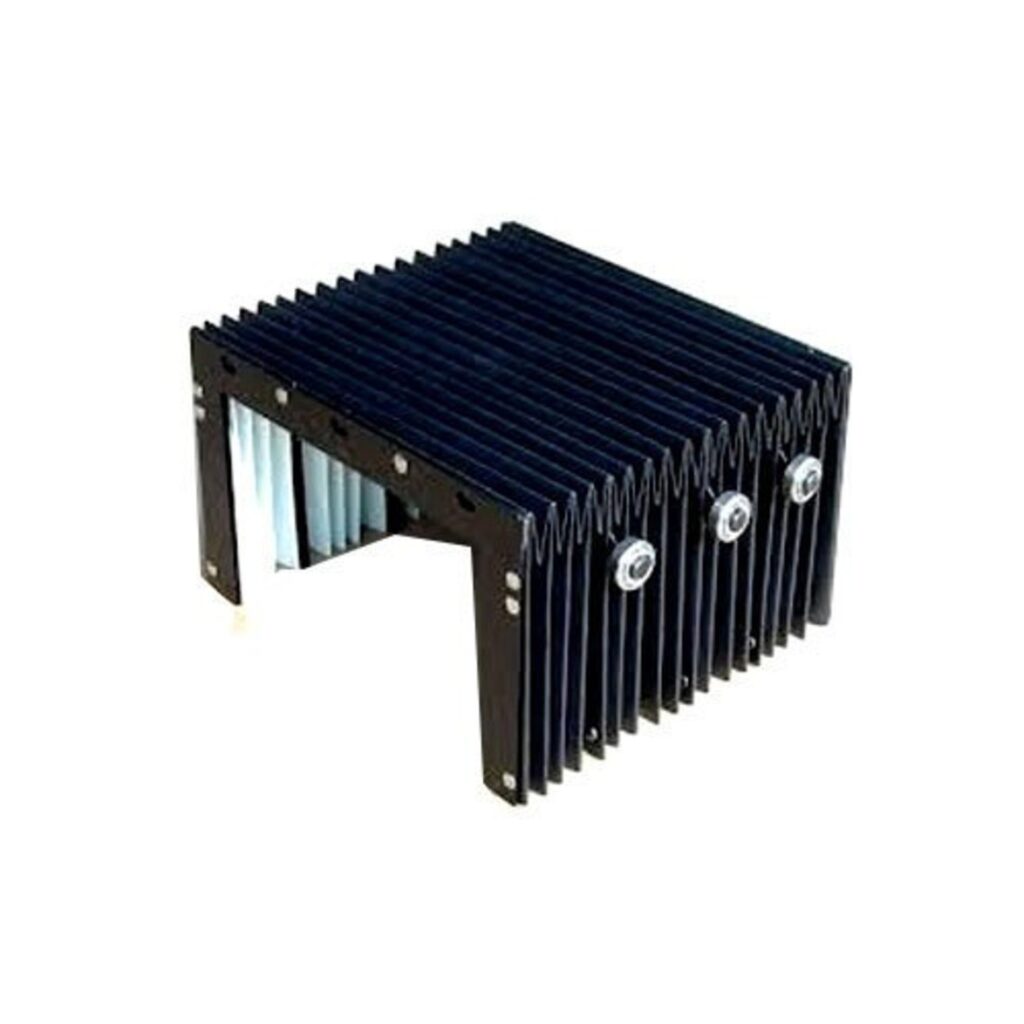

2.1 Durability and Strength

One of the key reasons nylon is preferred for bellow covers is its remarkable durability. Nylon is a synthetic material that can withstand harsh conditions, including exposure to oils, chemicals, and high temperatures. This ensures that the bellow covers retain their structural integrity even in demanding industrial environments.

2.2 Lightweight and Flexible

This makes Nylon Bellow Covers an ideal choice for CNC machines that require fast and smooth movements without added weight.

2.3 Resistant to Abrasion and Wear

https://en.wikipedia.org/wiki/Bellows

CNC machines often operate in environments where abrasive materials like metal shavings, dust, and coolant can cause significant wear and tear.

Flexibility and Seamless Movement

First and foremost, their remarkable flexibility allows for seamless movement alongside machine components, which ensures uninterrupted protection at all times. Moreover, this flexibility enables the covers to adapt easily to the machine’s movements without causing friction or obstruction. In addition, the design allows for quick installation, which means less downtime for your equipment.

Durability Under Harsh Conditions

In addition, the strong nylon construction not only resists wear and tear but also withstands harsh industrial conditions, making them exceptionally durable. Furthermore, these covers excel in resisting oils, chemicals, and high temperatures, thus making them suitable for a variety of demanding environments. Consequently, operators can trust that their machines remain protected even in the most challenging settings.

Reduced Maintenance Needs

By preventing dust, debris, and other contaminants from infiltrating critical machine parts, Nylon Bellow Covers significantly reduce the need for frequent repairs and maintenance. As a direct result, operational costs decrease while overall efficiency improves. Similarly, the lightweight design of these covers ensures that they do not add unnecessary strain to the machine, thereby promoting smoother and faster operations. Additionally, with less time spent on maintenance, operators can focus on maximizing productivity.

Customizable Fit

Moreover, the customizable nature of these covers allows them to fit a wide range of machine models and configurations perfectly, ensuring optimized protection tailored to specific equipment needs. Consequently, choosing Nylon Bellow Covers not only guarantees enhanced machine longevity but also assures reliable performance across various applications.

Key Features of Nylon Bellows

3.1 Seamless Protection

Nylon Bellow Covers are designed to offer seamless protection to the machine’s moving parts. By preventing contaminants from entering critical areas, they reduce the risk of breakdowns and malfunctions. This translates into fewer interruptions and less downtime, allowing for more consistent production cycles.

3.2 Temperature and Chemical Resistance

In many industrial settings, CNC machines are exposed to oils, coolants, and high operating temperatures, all of which can damage the machine’s internal components. Nylon Bellow Cover act as a barrier, protecting these parts from such exposure and ensuring smooth operation under challenging conditions.

3.3 Customizable Design

At Total CNC Solutions, we understand that every machine has unique requirements. That’s why we offer customizable Nylon Bellow Covers to suit your specific needs.

4. Benefits of Nylon Bellows

4.1 Extended Machine Lifespan

By protecting the moving parts of CNC machines from dust, debris, and contaminants, Nylon Bellow Covers help extend the life of the machine. Over time, wear and tear from exposure to harmful particles can lead to costly repairs and replacements.

4.2 Reduced Maintenance Costs

Nylon Bellow Cover minimize the need for constant cleaning and part replacement by keeping harmful contaminants away from the machine’s delicate components.

4.3 Enhanced Operational Efficiency

Nylon Bellow Cover ensure that the machine operates smoothly by reducing friction and preventing the accumulation of debris in the moving parts.

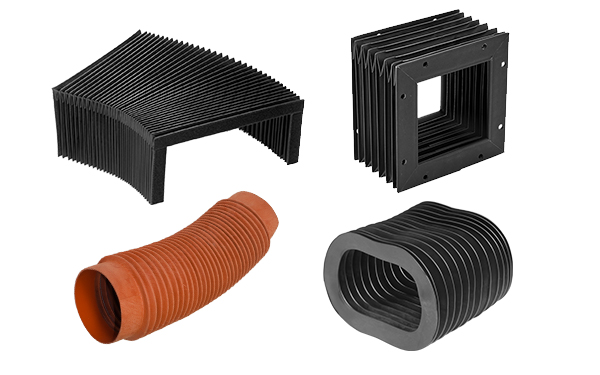

5. Applications of Nylon Bellow Covers

Some of the key applications include:

- Manufacturing: Protecting CNC machines, milling machines, and other equipment from debris and contaminants.

- Automation: Safeguarding robotic arms and automation equipment from wear and tear caused by repetitive movements.

- Medical Equipment: Ensuring the longevity of precision medical devices by protecting their moving parts from dust and particles.

- Aerospace: Protecting delicate machinery and instruments used in aerospace manufacturing from exposure to harsh elements.

6. Why Choose Total CNC Solutions for Nylon Bellow Covers?

At Total CNC Solutions, we pride ourselves on offering high-quality CNC machine protective equipment designed to meet the needs of today’s demanding industries.

Nylon Bellow Covers

When considering the best protection for CNC machines, Nylon Bellow Covers offer numerous compelling benefits. First of all, their flexibility allows for seamless movement with machine components, ensuring continuous protection without interruptions. Moreover, their robust nylon construction resists not only wear and tear but also exposure to harsh industrial conditions. In addition, these covers excel in resisting oils, chemicals, and high temperatures, making them suitable for various environments. Furthermore, by preventing dust, debris, and contaminants from reaching critical parts, Nylon Bellow Covers significantly lower the need for frequent repairs. As a result, maintenance costs decrease, and operational efficiency improves. Similarly, their lightweight design ensures that machine performance remains unaffected, allowing for smoother operations. Additionally, the customizable nature of these covers enables them to fit a wide range of machine models and configurations perfectly. Consequently, they deliver optimized protection tailored to specific equipment needs.

Conclusion: Invest in Nylon Bellow Covers for Maximum Protection

By offering seamless protection from contaminants, resisting harsh conditions, and reducing maintenance costs, these covers ensure that your mIn summary, when it comes to protecting your CNC machines, Nylon Bellow Covers represent a smart choice. Not only do they offer exceptional durability and flexibility, but they also significantly reduce maintenance needs, allowing for enhanced operational efficiency. Moreover, their customizable fit ensures that you get the perfect protection tailored to your specific machinery. As a result, investing in these covers not only extends the life of your equipment but also leads to long-term cost savings. Therefore, don’t wait any longer—take the proactive step to safeguard your machines today! By choosing Nylon Bellow Covers, you ultimately secure a brighter, more efficient future for your operations.

machines operate smoothly and reliably for years to come. At Total CNC Solutions, we offer customizable, high-quality Nylon Bellow Cover tailored to your specific needs, ensuring the best possible fit and performance for your machines.

Contact us today to learn more about our Nylon Bellow Cover and how they can help extend the life of your CNC equipment!