CNC Slide Bellow Covers: An Essential Shield for Precision and Longevity

In the world of CNC machining, maintaining precision, durability, and safety is paramount. One of the most critical components in safeguarding the CNC machine and ensuring its longevity is the CNC Slide Bellow Cover. Designed to protect machine tools from dust, debris, coolant, and other contaminants, these covers play a vital role in preventing damage to machine parts and enhancing operational efficiency. This post will delve into the importance of CNC Slide Bellow Covers, their features, types, and how they contribute to the overall performance of CNC machines.

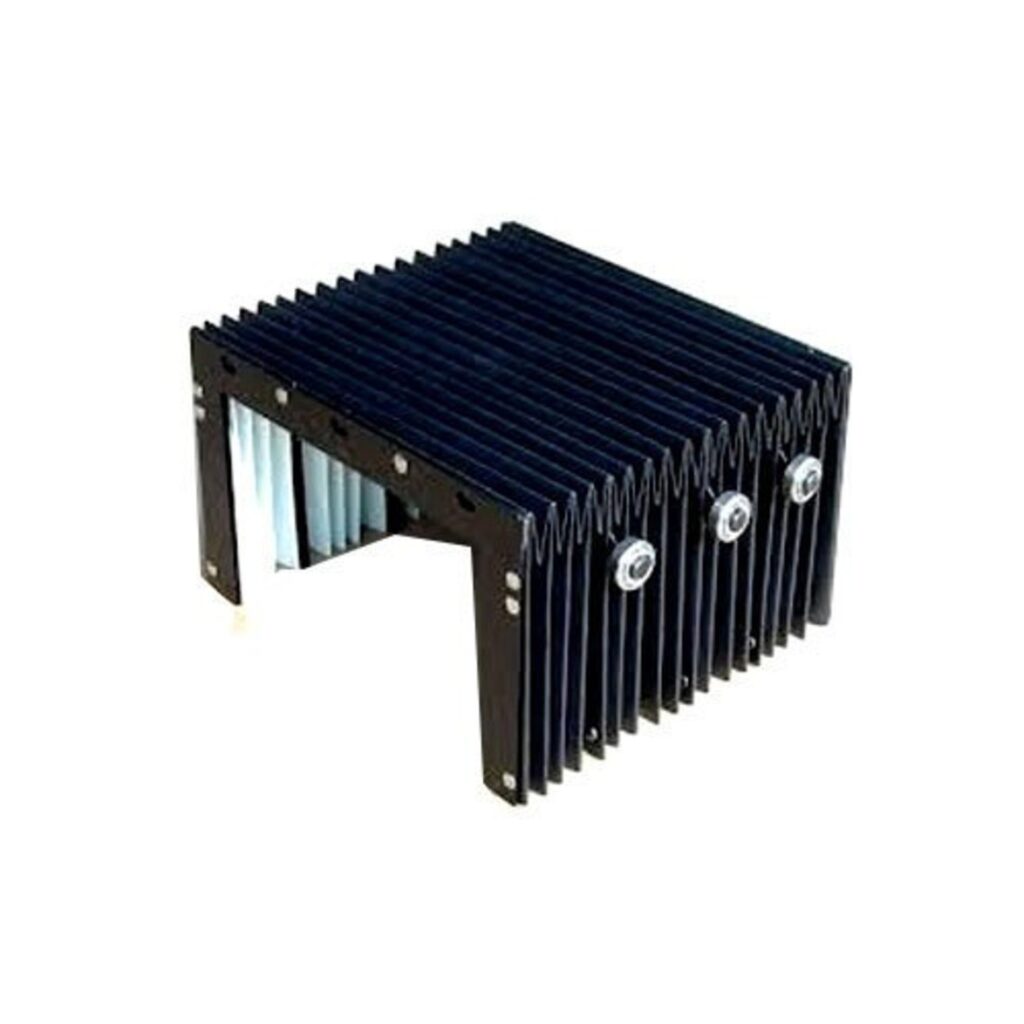

What is a CNC Slide Bellow Cover?

Machine Protective Bellow Covers

A CNC Slide Bellow Cover is a protective covering specifically designed to shield the sliding components of a CNC machine. As CNC machines are designed to perform precision tasks with a high level of accuracy, their exposed components—especially sliding parts—are vulnerable to wear and damage from the surrounding environment.

Key Features of CNC Slide Bellow Covers

https://en.wikipedia.org/wiki/Bellows

When choosing a CNC Slide Bellow Cover, several essential features make it an indispensable asset for CNC machines:

- Durability: Made from high-quality materials such as synthetic fabrics, elastomers, or PVC, these covers are built to withstand harsh machining environments. Their resistance to abrasion, chemicals, and temperature variations ensures long-lasting protection.

- Customizable Design: CNC Slide Bellow Covers are available in a wide range of designs to suit different machine configurations.

- Ease of Installation: The flexible nature of the bellow cover allows for quick installation and removal. This feature is particularly important during machine maintenance, where time is a crucial factor.

Types of CNC Slide Bellow Covers

There are different types of CNC Slide Bellow Covers, each designed to meet specific requirements based on the machine’s application. Here are a few common types:

- Rectangular Bellow Covers: These are the most widely used type and are suitable for machines with linear motion in rectangular configurations. They are ideal for protecting horizontal and vertical slides.

- Round Bellow Covers: Commonly used for spindles or circular components, round bellow covers are designed to protect machine parts with rotational or circular motion.

- Tandem Bellow Covers: These covers provide protection over a wide range of movements by connecting multiple bellows.

Why CNC Slide Bellow Covers Are Crucial for Machine Longevity

Transitioning to the broader benefits, CNC Slide Bellow Covers are vital in preserving the longevity and functionality of the machine. As a result, this minimizes the frequency of repairs and downtime, ultimately leading to lower maintenance costs.

Enhancing Safety with CNC Slide Bellow Covers

In addition to maintaining machine accuracy and longevity, CNC Slide Bellow Covers also enhance workplace safety. This could pose a significant risk to operators and other personnel working near the machine.

Conclusion

In the highly precise world of CNC machining, ensuring optimal machine performance and protection is essential. That’s where CNC Slide Bellow Cover come into play. Not only do they protect critical machine components from harmful contaminants, but they also significantly reduce the wear and tear that can accumulate over time. As a result, these covers help extend the lifespan of CNC machines, which ultimately leads to fewer repairs and lower maintenance costs.

Moreover, bellow covers play a vital role in enhancing machine efficiency. Because CNC machines rely on accurate movements for precision tasks, any disruption from debris or coolant can lead to compromised performance.

In addition to protection and precision, CNC Slide Bellow Cover also contribute to improved safety in the workplace. These covers effectively contain metal shavings, liquids, and other harmful materials, which helps create a safer environment for operators.

Furthermore, Total CNC Solutions recognizes that each machine has unique requirements. Whether your machine requires protection from heat, heavy debris, or liquids, we have the ideal cover to meet your needs.

Investing in CNC Slide Bellow Cover is not just about extending the life of your equipment—it’s about boosting overall productivity. In turn, this results in less downtime and improved business performance.

Thus, by choosing the right protective covers, you’re not only safeguarding your machines but also enhancing your operational workflow.